This blog will talk about the issues about biomass, biofuels and biochemical production from lignocellulosic biomass.

Tuesday, April 28, 2009

Thursday, April 23, 2009

Low Risk Biorefinery: more product streams

Bioethanol production often faces survival challenging due to its lower margin profit at low oil price and downturn economic recession, which always puts a sole-ethanol production business in a high risky situation. Although there is an incentive from government support with policy, funding, and tax credit, whether it is sustainable profitable will determine the future of this industry. The relatively safe way is to have multiple bio-product streams that are composed of high value-added biochemicals such as lactic acid, succinic acid, glucaric acid to reduce the risks.

US-DOE top 12 building blocks give us the direction.

Thursday, April 16, 2009

Monday, April 13, 2009

Paper mill sludge: a cheap sugar for biofuel/biochemicals

Modern paper companies produce large quantities of sludge when using recycled fiber. These sludges are the residue leftover from the paper recycling process and consist of unusable short cellulose fibers inks and dyes, clay, glues and other residue along with any chemicals used in the recovery process. The main disposal routes for paper sludge are land-spreading as agricultural fertilizer or incineration in CHP plants at the paper mill. However, the shortage of landfill space and more restrictive environmental regulations have made disposal more costly and less desirable.

A recent analysis of the sludges from a carton paperboard mill and a tissue paper mill indicating the cellulose are composed of 50-65% of total dry weight of sludge, which can be an important fiber source for biofuel and biochemical feedstock. These fibers with low amount of lignin make them more digestible for enzyme and the process is much simpler compared with the one from biomass. Prior to hydrolysis, there is a need for pre-cleaning or separation of the contaminants through mechanical/chemical process.

Thursday, April 9, 2009

The chemical kinetics of the sulfuric acid hydrolysis

The chemical kinetics of the sulfuric acid hydrolysis of softwood was determined by J.F.Seaman in 1945 as follows:

- a 100% increase in acid concentration causes an increase of 153% in the k1 cellulose-hydrolysis-rate kinetics constant, but that increase only caused the k2-sugar product-degradation kinetics constant to increase 103%.

- a 10 degree rise in C temperature causes an increase of approximately 190% in the k1- cellulose-hydrolysis-rate kinetics constant, but then k2-sugar-product-degredation kinetics constant increased only 130%.

Tuesday, April 7, 2009

Corn steep liquor: a sole cheap nutrient for fermentation

In the lab, expensive yeast and peptone extracts have been used to provide these nutrients for fermentation. However, the cost of the fermentation medium is also one of the principal factors that determines the economic viability of the ethanol production, it is very necessary to find low cost medium components that can supply all the nutritional requirements for good growth and fermentation activity.

Corn steep liquor (CSL) is a liquid by-product of wet milling process of maize-starch industry.It is a sole inexpensive source of nitrogen, vitamins, amino acids and other nutrients, which has been used in the lab study of fermentation and demonstrated the favorable effects compared with traditional complex media formulations for the fermentation.

Monday, April 6, 2009

Thar Process may bring a change on bioethanol recovery

Currently, bioethanol producers are facing another challenging time in its history for viability due to the bad economic situation, volatile commodity markets, and high feedstock cost (if use corns). Some corn-based ethanol producers have been forced to file for bankruptcy before any cellulosic ethanol commercialization takes off.

The key to change the fate of corn-cellulosic ethanol production is still upon the product cost. Cheap feedstock is the first priority. However, any new ideas or technologies that can drop current production cost will be expected in this industry.

Recently, Thar Process receives grant from the state of Pennsylvania for distillation replacement technology, i.e.use a high-pressure propane extraction to remove the high volumes of water from fermented broth and recover bioethanol to replace an existing ethanol plant’s conventional distillation. The propane used in the extraction process can be recycled; a significant energy savings is expected to save from bypassing the conventional distillation and molecular sieve drying steps.

We are looking forward to seeing the progress and economic evaluation of the process.

The key to change the fate of corn-cellulosic ethanol production is still upon the product cost. Cheap feedstock is the first priority. However, any new ideas or technologies that can drop current production cost will be expected in this industry.

Recently, Thar Process receives grant from the state of Pennsylvania for distillation replacement technology, i.e.use a high-pressure propane extraction to remove the high volumes of water from fermented broth and recover bioethanol to replace an existing ethanol plant’s conventional distillation. The propane used in the extraction process can be recycled; a significant energy savings is expected to save from bypassing the conventional distillation and molecular sieve drying steps.

We are looking forward to seeing the progress and economic evaluation of the process.

Wednesday, April 1, 2009

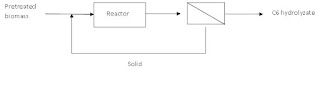

Recirculation of process streams from fermentation

When SSF fermentation is conducted via yeast, it is suggested to recirculate the process stream. The purpose is to maintain a high concentration of ethanol and dissolved solids and therefore to reduce the energy requirements in distillation and evaporation units ( expensive steps) and reduce fresh water usage. Based on the study by Alkasrawi et al (2002) for SSF process,when 60% of the fresh water was replaced by stillage, ther was no changed for ethanol yield and productivity but ethanol production cost reduced by 17%. When the liquid after SSF was partially recycled, 40% fresh water was replaced;final ethanol yield was not affected with initial productivity decreased; ethanol cost reduced 12%.

However, the disadvantage is that ccumulation of compounds released, or formed in the hydrolysis and fermentation steps may be toxic to enzymes or yeast.

So, we at least have effective enzymes and robust microorganisms for fermentation for this initial consideration of stream liquor circulation, right?

Subscribe to:

Comments (Atom)