It is quite a big amount in the pretreated hydrolyzate, which is toxic to microorganism at certain level. It is not economical by just removing it from the hydrolyzate. It should be recovered or utilized. Distillation is not efficient to recover it from the hydrolyzate. Membrane separation can achieve the goal but the capital and operating cost will kill the biorefinery if ethanol is the only product.

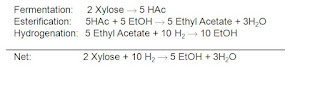

One of the approach is to produce ethanol indirectly, i.e first ferment xylose to acetic acid followed by esterification and hydrogenation. As a result, 2 unit of xylose can produce 10 unit ethanol with 10 unit hydrogen. The acetic acid can be used completely.

The questions are:

The questions are:

1. The yield and efficiency of fermentation to acetic acid

2. The cost of hydrogen

3. Cost of hydrogenation

4. more...

What are other alternatives to revover or remove acetic acid?