EPA Makes Progress Toward Approval of E15

ACE Urges Agency to Approve E15 and Higher for All Passenger Vehicles

This blog will talk about the issues about biomass, biofuels and biochemical production from lignocellulosic biomass.

EPA Makes Progress Toward Approval of E15

ACE Urges Agency to Approve E15 and Higher for All Passenger Vehicles

An intersting research paper with new findings: "xylobiose and higher xylooligomers were shown to inhibit enzymatic hydrolysis of pure glucan, pure xylan, and pretreated corn stover."

"Thus, b-xylosidase alone does not appear to be sufficient to hydrolyze high DP soluble xylooligomers, and supplementation with both xylanase and b-xylosidase appears desirable to realize high monomeric xylose yields, as found for pure xylan and AFEX and SO2 pretreated corn stover."

What about other oligomers such as mannooligomers in softwood?

All of these work but which one is more practical in terms of environmental issue and cost?

What about biopulping process?

The questions are:

The questions are:

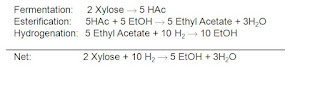

1. The yield and efficiency of fermentation to acetic acid

2. The cost of hydrogen

3. Cost of hydrogenation

4. more...

What are other alternatives to revover or remove acetic acid?

Uncoupling and intracellular anion acumination

–The drop in intracellular pH resulting from inflow of weak acids is neutralized by the action of plasma membrane ATPase, which pumps protons out of the cell at the expense of ATP hydrolysis. At high acid concentration, the proton pumping capacity of the cell is exhausted, resulting depletion of the ATP content, dissipation of the proton motive force, and acidification of the cytoplasm.

–However, the anionic forms of acetic, formic acid, are lipophobic and do not traverse the plasma membrane in both dissociated and undissociated form, causing a high rate of proton impart. The extent of intracellular anion accumination will be a function of the pH gradient over the plasma membrane.

Less heavily substituted phenolics are the most inhibitory compounds

–Phenols

–Vanillin

–Hydroxylbenzaldehyde

There, when we borrow the ideas from paper industry to treat biomass , somehow we should not turn our attention away from this industry. More we can take advantge of them.

Membrane Process is essentially a separation process based on molecular properties. The advanteges of membrane process include:

Ceretainly, the disadvantges exist, includng membrane fouling, low membrane life time, low selectivity, and high capital and operating cost.

Based on the driving forces, the following processes are defined as:

Pressure driven membrane processes

Microfiltration (MF)

-Simple screening mechanism

Pore size 0.01 μm - 10 μm

DP » 0.01 to 0.5 MPa

-Low pressure process

-Most effectively remove particles and microorganisms (bacteria)

-High flux

-Colloids/Macromole ---> theoretically pass through the membrane

Ultrafiltration (UF)

-Screening and Adsorption

Pore size 1 - 100 nm

DP 0.1 to 1 MPa

-Membrane is classified in terms of Molecular Weight-Cut off (MWCO) : 1000 - 100,000

-Two layers: a thin (0.1 to 0.5 µm), skin layer and a porous substructure support layer

-Separation of macromolecules

-Only surface deposition: no internal pore plugging; so, relatively easy to remove, irreversible

Nanofiltration (NF)

- NF Removes molecules in the 0.001 micron range

DP 0.5 to 6 MPa

MWCO: 0.2 to 200

-NF is essentially a lower-pressure version of reverse osmosis

-NF performance characteristics between reverse osmosis and ultrafiltration

Electrical driven membrane processes

-Electrodialysis (ED)

---------------------------------------------------------

•

Tubular membrane module

- Membrane is cast inside the support tube

- Tubular membranes have a diameter of 5 - 15 mm

- High SS tolerance

- Flow is usually inside out

-Mainly MF and UF

- Low packing density, high prices per module

• Hollow fibre membrane module

- Consists of a bundle of hundreds and thousands of hallow fiber

- Entire assembly is inserted into a pressure vessel

- Feed can be applied inside of the fiber (inside-out flow) outside (outside-in flow)

- Highest packing density of all.

- Hollow fiber is used mainly for NF and RO

•Spiral wound membrane module

- Flexible permeate spacer is provided between two flat sheet membranes

- Membrane: sealed three side and open side is attached to perforated pipe

- Flow is in a spiral pattern.

- Membrane envelop is spirally wound along with a feed spacer

- Filtrate is collected within the envelop and piped out

- Packing density:high

- RO and NF

• Plate and frame

--------------------------------------------------

Membrane Fouling: Deposition or accumulation of solids on the membrane.

Fouling causes resistance to flow through the membrane and eventual decline in overall flux.

Three major mechanisms of resistance flow:

-Pore narrowing

-Pore plugging

-Gel/cake formation due to concentration polarization

But what about the cost?

The techniques can be divided into four major categories based on the physical mechanisms:

Cell entrapment is a simple and useful method to provide a simulation of high-density cells used in small-scale bioreactors where a cell recirculation method with e.g. filter and continuous centrifuge is rather difficult. But there is a need for using the cell entrapment method in industry due to additional cost of immobilization material.

Self-aggregation of cells leading to formation of a flock and easy sinking is very useful for cell recirculation, and thus performs cell retaining. Yeast has a natural flocculation capability which is usually employed in the brewing industry. The flocculation of yeast is a reversible, asexual and calcium-dependent process. Lectin-like proteins, so-called flocculins, which stick out of the cell walls of flocculation cells, selectively bind mannose residues present in the cell walls of adjacent yeast cells. Calcium ions in the medium are needed in order to activate the flocculins. Once the yeast forms flocks, the separation of cells from broth can easily be carried out by sedimentation; thus cell recirculation is performed without any force-driven separation, i.e. filtration and centrifugation.

A large number of aliphatic acids are present in dilute-acid hydrolyzates originated from wood extractives, lignin degradation and sugar degradation.

The undissociated acids are harmful to the cells and inhibit cell growth. They are liposoluble and thus can diffuse across the plasma membrane into cytosol and may dissociate intracellularly. In order to maintain intracellular pH, protons must be transported across the membrane by the action of plasma membrane ATPase. This results in an increase of ATP consumption, and thereby causes lower biomass yield. In anaerobic conditions, ATP generation is achieved by the ethanol production pathway, resulting in higher ethanol yield at the expense of biomass formation. However, above critical extracellular concentration of undissociated acid, the diffusion rate of undissociated acid can exceed the transport capacity of the plasma membrane ATPase, and intracellular acidification occurs. It is found that the limit of extracellular pH at different acetic acid concentrations which allow yeast to grow. It was found that growth was possible at a pH not less than of 4.7 in cultivation containing 10 g/L acetic acid. Therefore, acetic acid is innocuous if it exists in low concentration or the cultivation is carried out at a pH higher than the extracellular pH limit.

Phenolic compounds

There are a number of phenolic compounds recognized in lignocellulosic hydrolyzates, including

These compounds are mainly liberated from lignin degradation in addition to aromatic wood extractives. The phenol aldehydes and phenol ketones were found as the worst inhibitors. Moreover, it was also shown the low molecular weight phenolic compounds are more toxic.

Phenolic compounds are considered to be important inhibitors due to their inhibitory effect in fermentation of lignocellulosic hydrolyzates. These compounds partition biological membranes and cause loss of integrity, hence disturb their ability to serve as selective barriers and enzyme matrices. The inhibition mechanism of phenolic compounds has not been elucidated yet.

Studies in inhibitory action of phenolic compounds have been carried out using higher concentrations than are actually present in the hydrolyzates. The water solubility of phenolic compounds is limited and depends on the composition of the liquid, which is different in hydrolyzates and the defined medium; therefore it is possible that the concentration at which the microorganism suffered has been lower. In addition, S. cerevisiae assimilates vanillin, hydroxybenzaldehyde, and syringaldehyde during fermentation, while growth has been reported on cathecol, recorcinol.

Furan compounds

Furfural and 5-hydroxymethyl furfural (HMF) have been found as further hydrolysis products of pentoses and hexoses respectively. Pentoses form furfural in high yield; but if the furfural is not removed as formed, it partially condenses into high-molecular-weight materials. By an analogous process, hexoses yield HMF which, on continued heating, yields levulinic acid and formic acid. Furfural has been reported to be a strong inhibitor for S. cerevisiae. The furfural concentration above 1 g/L was found to decrease significantly the CO2 evolution rate, the cell multiplication and the total viable cell number in the early phase of fermentation. During anaerobic fermentation, reduction of furfural to furfuryl alcohol occurs with high yields, while furoic acid is produced from oxidation of furfural during aerobic cultivation. In both cases, NADH-dependent alcohol dehydrogenase (ADH) is believed to be responsible for furfural conversion in yeasts.

HMF is chemically related to furfural and thus has similar inhibitory effects as furfural, except that it has a lower conversion rate which might be due to lower membrane permeability. It is also discovered that an addition of 4 g/L of HMF decreased the CO2 evolution rate (32%), ethanol production rate (40%), and specific growth rate (70%). However, these inhibitory effects were less than those caused by the same amount of furfural, and thus HMF cannot be considered as acutely toxic as furfural for growth and fermentation of S. cerevisiae.

The conversion rate of furfural is much faster than the conversion rate of HMF. Furthermore, HMF is converted to 5-hydroxymethyl furfuryl alcohol with a similar mechanism as it was shown in the case of furfural conversion.